Innovative Solutions to meet your needs

ESC has been providing controls designs and programming services for over 25 years as a part of our ESC, Inc. Consulting Engineers company. These capabilities will continue as a new division of ESC, Inc. called "ESC Integration Services" making their capabilities more accessible to clients seeking Integration Services from an experienced firm.

We keep good company.

Below are just a few of the companies we’ve partnered with.

ESC Integration specializes in robust operator and maintenance friendly integration solutions to fit your needs.

ESC, Inc. has been providing controls design and programming services for more than 25 years as a complement to our engineering designs. Many of our clients become aware and utilize our Integration capabilities while seeking our consulting engineering services. However, we also recognize that many more potential clients exist that may not be aware of the full range of services offered by our talented team, which includes our integration services. For these reasons we have decided to launch ESC Integration Services, a new division of ESC, Inc. ESC Integration Services will continue to support and complement ESC engineering designs like we have done for over 25 years, while making our Integration team's skills more accessible to clients who are looking for the services of an integration firm.

Integration services

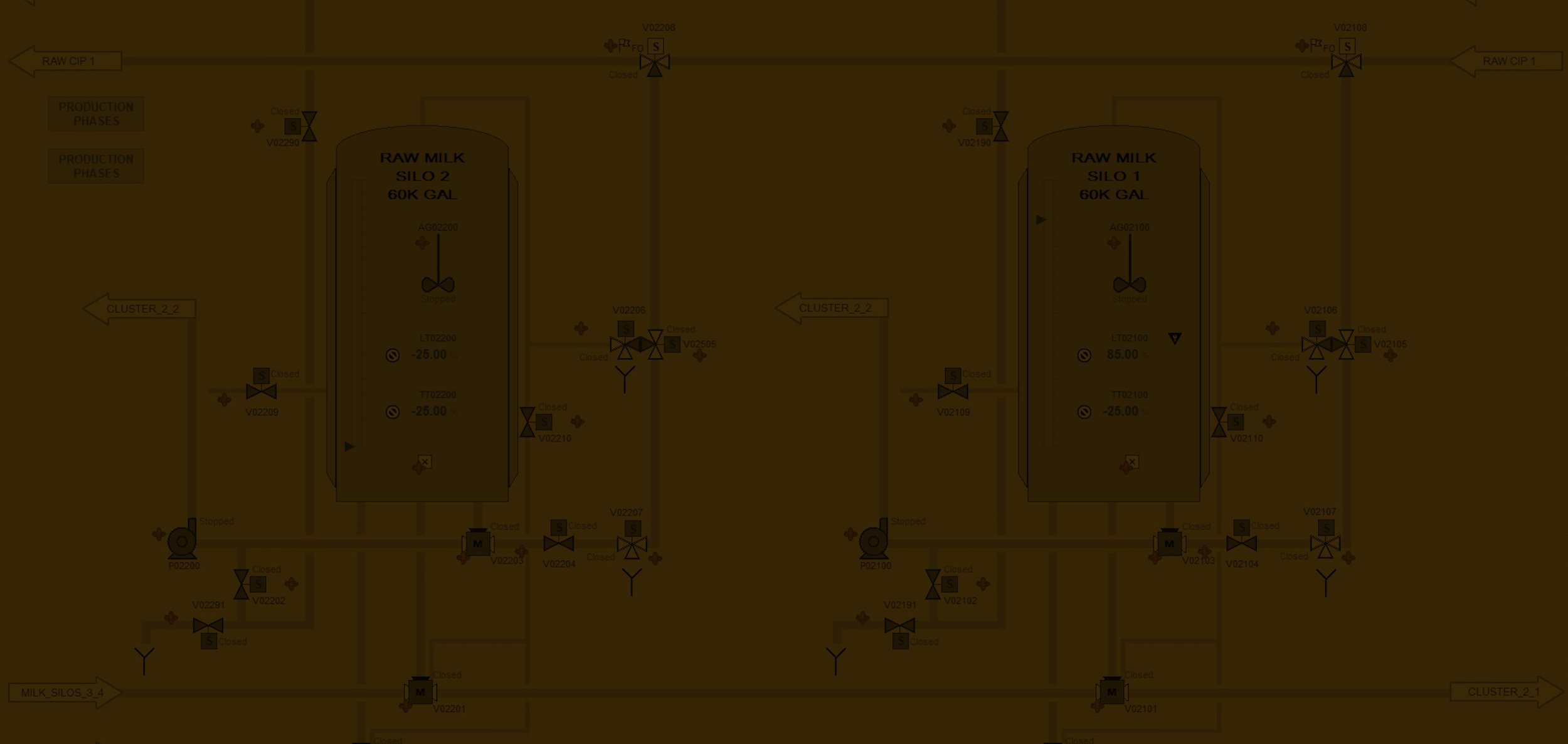

Today’s Industry requires integration solutions that are both operator and maintenance friendly. Our Electrical Design and Automation teams collaborate to develop tailored strategies. Today’s solutions require an understanding of how IT/OT technology is converging with the Industrial automation PLC/PAC world. System automation requirements range from full server deployed SCADA with recipe management and reporting, to highly distributed I/O multiple controller systems, that can provide high availability through redundancy, or a simple stand-alone, HMI/OIT station. We strive to align with your site's best practices and requirements while meeting your production needs. We also understand that the start-up and commissioning of an integrated system is crucial to the overall success of a project, and we take pride in delivering complete solutions that ensure successful start-ups.

What makes us special?

In plant experience

Several of our team members have come from client’s / plant’s side

Heart for service because we know our client’s needs (at all levels of the organization)

Process knowledge

Willingness to look at root cause of automation issues and get our hands dirty to improve automated processes (even if the issue is not programming related).

Flexibility

Allen-Bradley, Aveva, Siemens

S-88 compliant PAX down to more basic ladder logic code

ESC Integration Services Recognized Associations

Why ESC?

ESC is blessed with a technically talented team of engineers, programmers, and technicians that ALSO have a heart for service. Our experience allows us to serve large and small clients while the relatively small size of our firm allows us to be responsive to our client’s ever changing needs. By listening and responding to our clients needs, we can support Fortune 500 companies (and those that are much smaller) on projects of any size.

-

While there are often similar systems in our clients’ facilities, we understand that every production facility has different needs and preferences. ESC has the experience to understand what types of control systems work well for various operations and we listen to the clients to understand what they are looking for before we develop the proposed solution. From software/HMI bench tests hosted at our office, to onsite IQ/OQ/PQ support, to custom training solutions. Our flexibility in the implementation of hardware/software solutions allows us to deliver a customized solution to fit your needs.

-

Our team of designers work hand in hand with the automation team to design and build control panels that work well with new equipment while also integrating seamlessly with controls systems and architecture that may already exist in the plant.

-

ESC Integration Services has extensive experience in developing code that is compliant with ANSI/ISA88 Batch Control Standards. This model has been widely adopted by the Industrial Process and Pharmaceutical industries. This standard allows our clients to make and track batches of products in a way that is configurable using parameters and able to be configured and troubleshot through the HMI. We have developed a library of customized process objects developed using AB’s Library of Process Objects. Our implementation of login controls also allows for tracking of batch/recipe changes or other modifications to equipment level settings.

-

Our clients need for throughput often demands that there are some repetitive or challenging tasks that need to be done with a high degree of repeatability and uptime. Our experience as a Certified Systems Integrator for Universal Robots allows us to see what options may exist to automate these tasks in a safe and economical way that are also easily updated for new/different tasks.

-

Modern industrial controls systems require much more interaction with IT systems than ever before. ESC has the IT/OT knowledge to help you develop your system architecture to maximize the output of the production systems while interacting with the IT systems in a way that makes sense and minimizes downtime related to software updates, network outages, etc. that may be caused by connections to the IT systems. ESC can also assist our clients’ IT professionals in setting up the servers needed to run the production and data capture systems that are common in today’s plants.